HACCP Management System Certification vs HACCP International Product Certification – A critical distinction

There seems to be some confusion about ‘HACCP’ certification requirements for non-food products and services supplied to the food industry. This article explains the difference between ‘HACCP’ food safety management certification and product certification provided by HACCP International.

Background

Food Processors and handlers that operate in accordance with world’s best practice food safety schemes will usually have food safety certification – commonly known as ‘HACCP Certification’. There are a number of best practice certification schemes including BSC, SQF, FSSC 2200, and the World Health Organisation’s (WHO’s) Codex HACCP. They all have ‘HACCP’ as their foundation and some have additional requirements for quality and food security.

Almost all food companies that are certified to these standards are required to show the non-food products and services used in food handling and processing are ‘fit for purpose’, thereby eliminating the unintentional introduction of further food safety hazards into the food facility.

Food handling, in this context, includes food manufacturers, packers and distributors, caterers and restaurants and might extend to retailers. It will also include manufacturers of products that have long term food contact items (such as the inner packaging for cereal boxes or the can that contains a soft drink that are treated like food in our industry).

There are a number of certification bodies in Australia, that certify food businesses to some or all of these schemes such as SGS, BSI, Intertek and HACCP Australia. These certifications relate to the food safety management systems. They do NOT refer specifically to non-food products or services used by a food business process and are not product or SKU specific – unless it as an actual food product or ingredient.

This is really important. The food businesses need their food safety processes certified with food safety management system certification. The suppliers of non-food products and services to them need to demonstrate their products are fit for use therein and that is best done through product certification.

Just as product certification is inappropriate to food businesses, HACCP system or Codex HACCP certification is totally inappropriate to suppliers of products and services such as gloves, lubricants pest control products and services, and flooring products, as these suppliers do not handle food! It’s the product characteristics that are important to the food business.

Just as product certification is inappropriate to food businesses, HACCP system or Codex HACCP certification is totally inappropriate to suppliers of products and services such as gloves, lubricants pest control products and services, and flooring products, as these suppliers do not handle food! It’s the product characteristics that are important to the food business.

So, food companies are responsible for all materials brought into the food facility. Those responsible for choosing which products are used need confirmation, on a product-by- product basis, of the product’s food safe characteristics and its fitness for purpose through a documented due diligence process. Such due diligence can be conducted by the food company themselves or through third party product certification.

Some background on Product Certification issued by HACCP International

All food businesses will use non-food materials and equipment in processing and handling. The food safety schemes mentioned above will require them to ensure that those non-food materials and consumables that have incidental or short-term contact with food, or have a significant impact on food safety, are fit for their purpose and don’t, in themselves, present a food safety risk. Examples of such products include incidental contact items such as disposable gloves, lubricants, paper products and sanitisers, thermometers, fridges and conveyor belts. Examples of items that are not meant to touch food but still present significant food safety risks include flooring, walling, drainage and lighting. This risk also extends to some services supplied to the food industry, such as pest control, cleaning services or calibration services.

Food business will need to demonstrate a process for confirming that products used are suitable. The product assessment process can be arduous and technically difficult, in that it usually requires full knowledge of the product’s material, toxicity, design, lab results and accuracy/ verification of claims made about these products. For this reason, buyers and sellers alike might rely on specialist third party product certification body that have the specialist analytical skills and systems and the food technology resources.

It is this role that HACCP International undertakes when certifying non-food products as food safe equipment, materials and services. This certification is not a management system certification of food operations.

Product certification not only requires standard requirements against which a product can be measured but, in the case of products supplied to the food industry, a hazard analysis as well. HACCP International certify to HACCP Australia’s proprietary standards designed to meet the food industry’s requirements of the product type.

Furthermore, certain products might also require a quality management system certification. In a food processing operation, this can be combined with food safety in management system certification, however, it cannot be combined with product certification, especially when componentry might come from many different sources – and they won’t be food businesses! ISO 9001 or a robust and audited QA system is a prerequisite of product certification for certain product categories to ensure traceability, good manufacturing practices and quality management practices.

An easy way for food companies to demonstrate all of the materials brought into the food facility are suitable is to purchase HACCP International certified products and services. A copy of the certificate can be used as evidence during the third-party audit. A helpful selling tool for the supplier.

Click to view the HACCP International Food Safe Equipment, Products and Services registers

Developing and maintaining a food safety programme is a lot of work

A food safety programme involves identifying the hazards in all steps in the production process, a risk assessment of the sources and types of the hazards. Identification of critical control points (CCPS) and ongoing monitoring and maintenance of records of the CCPs. It is an onerous task and requires considerable management, but is essential in keeping food safe. That said, it is not appropriate for manufacturers of non-food products.

What is important is the nature of the actual products – and that is what product certification addresses.

Get the certification you need

For this reason, it is important to determine what is wanted in terms of food safety. Is it product certification to meet the due diligence requirements and the operating standards of food customers, or is it CODEX HACCP food safety certification? Check what you are getting and ensure that it is standards based and what you need.

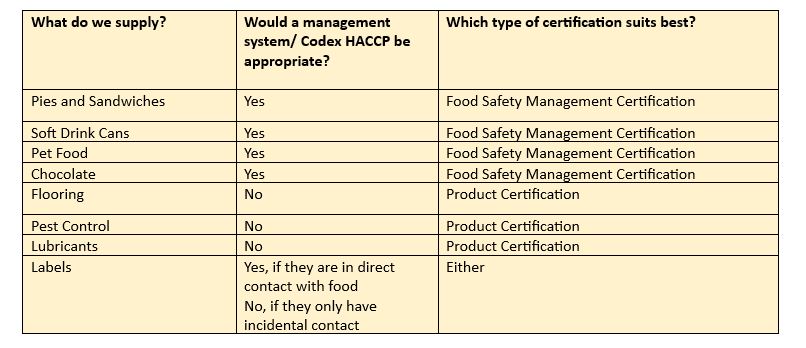

Some examples of the certification types recommended:

I hope this goes someway to clarifying the confusion between Codex HACCP based food safety certification and product certification by HACCP International.

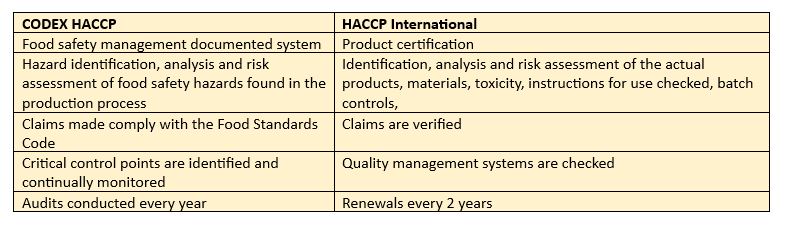

Comparison CODEX HACCP certification vs HACCP International Certification

In summary, Codex HACCP Food safety management system Certification is for food businesses and sometimes mistakenly sought by suppliers of non-food products. It can result in requiring unnecessary monitoring records and costly annual audits, and still not provide the food company with assurances that the non-food product or service is suitable for use in the food facility.

Please feel free to ask us, at any questions relating to certification. We will always ensure you are looking for the right sort of certification in the first place. We will tell you whether you should be considering a food safety management system, product certification, both or neither. Once you know what you want, you can shop around with confidence. Email info@haccp-international.com

Rachel Meryment Certification Manager HACCP International

Clive Withinshaw,

Director

HACCP International